Organic fertilizer is not effective? What is the fundamental reason?

Date:2024/08/09

When we find that the fertilizer effect of organic fertilizer is not satisfactory, in addition to the possible purchase of unqualified or insufficient nutrients, poor process products, but also need to examine the problem from multiple dimensions.

1. Soil problems are serious

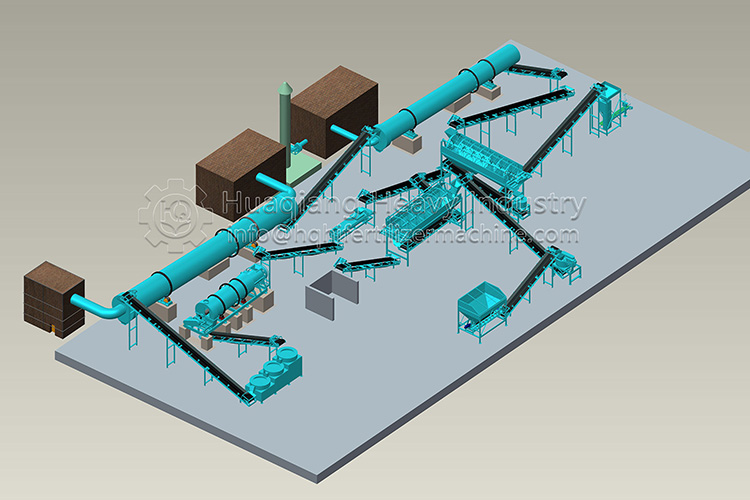

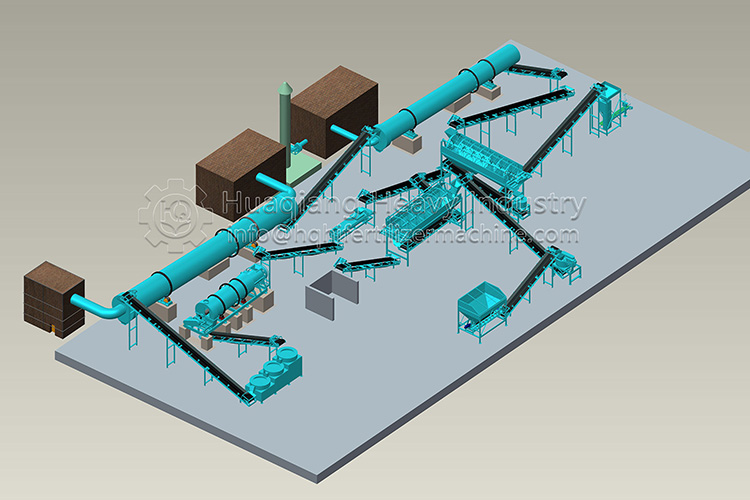

First, we must face up to the current soil problems, such as soil compaction and salinization. "Ice is not built in a day", soil problems are not caused by one or two days, then to improve the soil is not overnight. The improvement effect of organic fertilizer on soil is a gradual process, which depends on continuous input and correct use. At this point, the quality control of Organic Fertilizer Production Line is particularly important. Whether it is a Rotary Drum Granulator, or a Disc Granulator, it is necessary to strictly control the ratio of raw materials, mixing uniformity and particle molding quality in the production process to ensure that the produced organic fertilizer has stable fertilizer efficiency and good soil improvement effect.

2. Selection and application of organic fertilizer

Different crops have different nutrient requirements, so choosing the right organic fertilizer type and application method is crucial. On the Production Line, by precisely controlling the ratio and mixing process of various nutrients, it is possible to produce customized organic fertilizers tailored to the needs of different crops. At the same time, when farmers use organic fertilizers, they also need to fertilize in strict accordance with the guidance of manufacturers or professional agricultural technicians to ensure that fertilizers can play a full role. For example, the proportion of water-soluble fertilizer of organic fertilizer is appropriate, blindly shrinking or expanding the proportion may receive counterproductive effects; When many farmer friends use organic fertilizer, they fail to cover the soil in time, and the fertilizer is only on the surface of the soil, and can not fully contact the soil, and can not play the effect of improving the soil.

3. Organic fertilizer is usually slow-release fertilizer, fertilizer is slow but fertilizer efficiency is long.

This property gives organic fertilizers significant advantages in improving soil structure and providing long-term nutrient supply. However, this also requires us to take environmental factors into account when applying fertilizer. Compared to fertilizers, the release time of organic fertilizers depends on a number of factors, such as temperature, humidity, and soil type. In warm, humid environments, organic fertilizer is usually released within six months to a year. In a dry environment, the release time of organic fertilizer may be extended. Therefore, when selecting organic fertilizers and making fertilization plans, it is necessary to fully consider the local climatic conditions and soil conditions.

Finally, from the perspective of Organic Fertilizer Production Line,Rotary Drum Granulator and Disc Granulator are key equipment in the production process, and their performance and quality directly affect the quality and fertilizer efficiency of organic fertilizer. The Rotary Drum Granulator makes the material form granule through rotation and friction, which has the advantages of large output and uniform particle. The Disc Granulator is suitable for the granulation of a variety of materials, and has the characteristics of simple operation and strong adaptability. When selecting and using these devices, factors such as their performance parameters, maintenance costs, and the skill level of the operator should be fully considered.

1. Soil problems are serious

First, we must face up to the current soil problems, such as soil compaction and salinization. "Ice is not built in a day", soil problems are not caused by one or two days, then to improve the soil is not overnight. The improvement effect of organic fertilizer on soil is a gradual process, which depends on continuous input and correct use. At this point, the quality control of Organic Fertilizer Production Line is particularly important. Whether it is a Rotary Drum Granulator, or a Disc Granulator, it is necessary to strictly control the ratio of raw materials, mixing uniformity and particle molding quality in the production process to ensure that the produced organic fertilizer has stable fertilizer efficiency and good soil improvement effect.

2. Selection and application of organic fertilizer

Different crops have different nutrient requirements, so choosing the right organic fertilizer type and application method is crucial. On the Production Line, by precisely controlling the ratio and mixing process of various nutrients, it is possible to produce customized organic fertilizers tailored to the needs of different crops. At the same time, when farmers use organic fertilizers, they also need to fertilize in strict accordance with the guidance of manufacturers or professional agricultural technicians to ensure that fertilizers can play a full role. For example, the proportion of water-soluble fertilizer of organic fertilizer is appropriate, blindly shrinking or expanding the proportion may receive counterproductive effects; When many farmer friends use organic fertilizer, they fail to cover the soil in time, and the fertilizer is only on the surface of the soil, and can not fully contact the soil, and can not play the effect of improving the soil.

3. Organic fertilizer is usually slow-release fertilizer, fertilizer is slow but fertilizer efficiency is long.

This property gives organic fertilizers significant advantages in improving soil structure and providing long-term nutrient supply. However, this also requires us to take environmental factors into account when applying fertilizer. Compared to fertilizers, the release time of organic fertilizers depends on a number of factors, such as temperature, humidity, and soil type. In warm, humid environments, organic fertilizer is usually released within six months to a year. In a dry environment, the release time of organic fertilizer may be extended. Therefore, when selecting organic fertilizers and making fertilization plans, it is necessary to fully consider the local climatic conditions and soil conditions.

Finally, from the perspective of Organic Fertilizer Production Line,Rotary Drum Granulator and Disc Granulator are key equipment in the production process, and their performance and quality directly affect the quality and fertilizer efficiency of organic fertilizer. The Rotary Drum Granulator makes the material form granule through rotation and friction, which has the advantages of large output and uniform particle. The Disc Granulator is suitable for the granulation of a variety of materials, and has the characteristics of simple operation and strong adaptability. When selecting and using these devices, factors such as their performance parameters, maintenance costs, and the skill level of the operator should be fully considered.