How to deal with cow dung most make money?

Date:2024/08/19

Most small cattle farms choose to process cow manure into organic fertilizer when dealing with cow manure, which can not only avoid the pollution of the environment by cow manure and meet the requirements of environmental protection, but also turn waste into treasure. It can also bring extra income for cattle farms through the sales of organic fertilizer and realize the recycling of resources.

For small cattle farms with limited budget, powdered organic fertilizer production line is favored because of its low investment cost, simple operation and quick effect. However, if you want to further improve the added value of products and meet the diversified market demand for granular organic fertilizer, you can consider adding granulation links on the basis of powdered Organic Fertilizer Production Line, such as introducing Rotary Drum Granulator or Disc Granulator.

Rotary Drum Granulator

The Rotary Drum Granulator is one of the ideal equipment for the production of granular organic fertilizer. Through the interaction between the inner wall of the rotating drum and the scraper or the stirring blade, the powder material is gradually extruded and rolled into spherical particles. The equipment has the advantages of large yield, high granulation rate, good particle strength and so on, and can adapt to the granulation needs of a variety of raw materials, including cow manure organic fertilizer with moderate water content. The use of Rotary Drum Granulator can significantly improve the appearance quality and market competitiveness of organic fertilizer, and attract more consumers who pay attention to product form.

Disc Granulator

In contrast, Disc Granulator are known for their simple structure and easy operation and maintenance. It uses the rotating disc surface to make the material roll into balls under the action of centrifugal force, which is suitable for pelleting materials with moderate or slightly lower viscosity. Although the output of the Disc Granulator may be slightly inferior to that of the Rotary Drum Granulator, satisfactory results can also be achieved in the treatment of some specific types of cattle manure organic fertilizer. In addition, the cost of Disc Granulator is relatively low, making them a cost-effective option for small cattle farms with limited budgets.

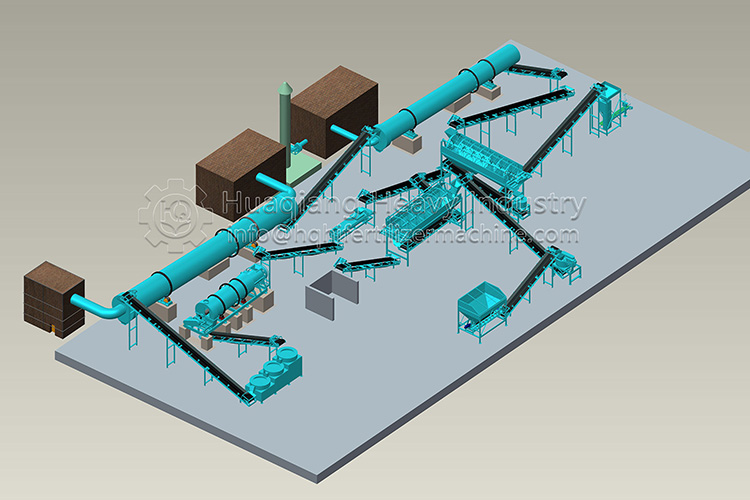

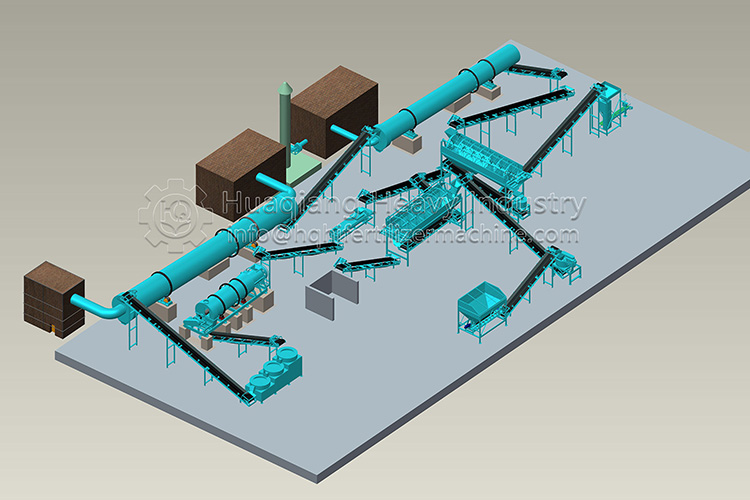

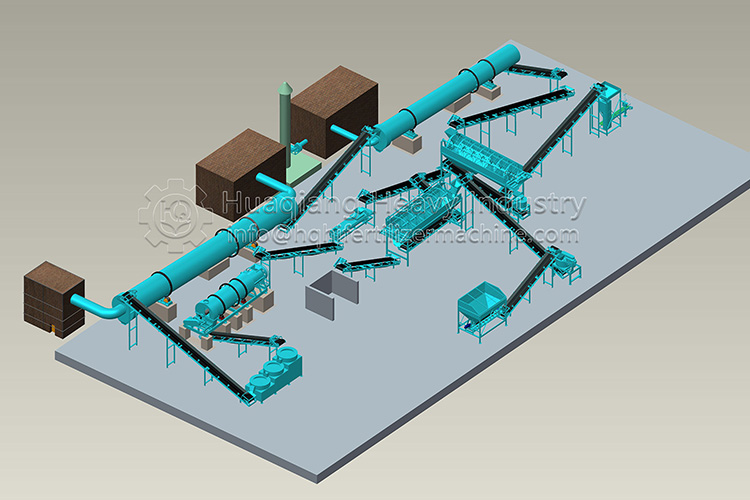

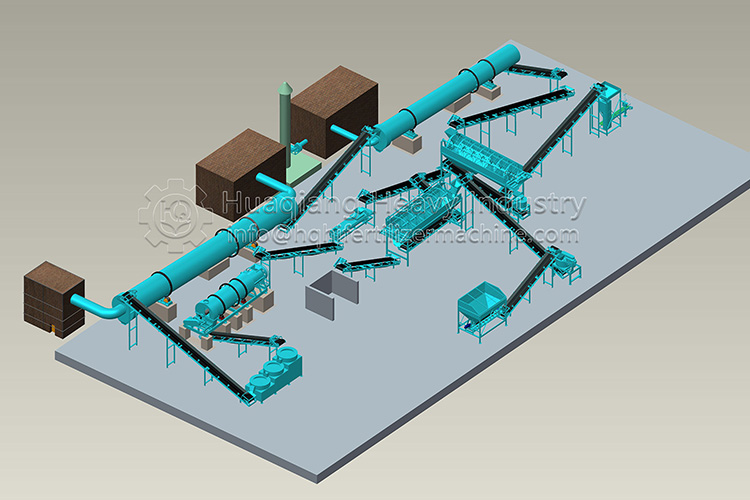

Complete production line configuration proposal

In the configuration of small Organic Fertilizer Production Line, in addition to the core granulation equipment, it is necessary to consider the equipment of raw material pretreatment, mixing, drying, screening and packaging. For example, raw material pretreatment may include grinders to ensure uniform particle size of cow manure; The mixer is used to fully mix various additives with cow manure to improve the quality of fertilizer; The drying equipment is used to remove the excess water generated in the granulation process to ensure the hardness and stability of the particles; The screening machine is used to separate unqualified large particles and small particles to ensure the quality of finished products; Finally, the packaging machine is used to separate the qualified organic fertilizer for easy storage and transportation.

In the treatment of cow manure, small cattle farms can not only realize the effective use of cow manure, but also significantly improve the added value and market competitiveness of organic fertilizer products by introducing powdered Organic Fertilizer Production Line and combining with granulation equipment such as Rotary Drum Granulator or Disc Granulator, so as to find the best balance between environmental protection and economic benefits.

For small cattle farms with limited budget, powdered organic fertilizer production line is favored because of its low investment cost, simple operation and quick effect. However, if you want to further improve the added value of products and meet the diversified market demand for granular organic fertilizer, you can consider adding granulation links on the basis of powdered Organic Fertilizer Production Line, such as introducing Rotary Drum Granulator or Disc Granulator.

Rotary Drum Granulator

The Rotary Drum Granulator is one of the ideal equipment for the production of granular organic fertilizer. Through the interaction between the inner wall of the rotating drum and the scraper or the stirring blade, the powder material is gradually extruded and rolled into spherical particles. The equipment has the advantages of large yield, high granulation rate, good particle strength and so on, and can adapt to the granulation needs of a variety of raw materials, including cow manure organic fertilizer with moderate water content. The use of Rotary Drum Granulator can significantly improve the appearance quality and market competitiveness of organic fertilizer, and attract more consumers who pay attention to product form.

Disc Granulator

In contrast, Disc Granulator are known for their simple structure and easy operation and maintenance. It uses the rotating disc surface to make the material roll into balls under the action of centrifugal force, which is suitable for pelleting materials with moderate or slightly lower viscosity. Although the output of the Disc Granulator may be slightly inferior to that of the Rotary Drum Granulator, satisfactory results can also be achieved in the treatment of some specific types of cattle manure organic fertilizer. In addition, the cost of Disc Granulator is relatively low, making them a cost-effective option for small cattle farms with limited budgets.

Complete production line configuration proposal

In the configuration of small Organic Fertilizer Production Line, in addition to the core granulation equipment, it is necessary to consider the equipment of raw material pretreatment, mixing, drying, screening and packaging. For example, raw material pretreatment may include grinders to ensure uniform particle size of cow manure; The mixer is used to fully mix various additives with cow manure to improve the quality of fertilizer; The drying equipment is used to remove the excess water generated in the granulation process to ensure the hardness and stability of the particles; The screening machine is used to separate unqualified large particles and small particles to ensure the quality of finished products; Finally, the packaging machine is used to separate the qualified organic fertilizer for easy storage and transportation.

In the treatment of cow manure, small cattle farms can not only realize the effective use of cow manure, but also significantly improve the added value and market competitiveness of organic fertilizer products by introducing powdered Organic Fertilizer Production Line and combining with granulation equipment such as Rotary Drum Granulator or Disc Granulator, so as to find the best balance between environmental protection and economic benefits.