Ammonium sulfate fertilizer extrusion pellet production line

Date:2024/08/16

Working principle of Fertilizer Granules Compaction Machine:

Fertilizer Granules Compaction Machine is the use of pressure to directly squeeze the material into the finished product granulation process, especially suitable for the granulation of thermal sensitive materials. There are usually two types of extrusion machinery: one is the push type granulator; The other is Fertilizer Granules Compaction Machine. The two types have various forms due to their different structures. The water content of the feed of the push and press type extrusion granulator is usually 5% ~ 8%, and the cylindrical product is obtained after extrusion, and the compound fertilizer product with water content less than 5% is obtained by cooling. The water content of the feed of the pelleting Fertilizer Granules Compaction Machine can be lower, foreign reports can be between 0.5% and 1.5%, the belt material obtained by extrusion is broken by the Chain Crusher, and the double screen is screened to get the bulk or compound fertilizer products with edges and angles. The fine powder after crushing is returned to the extrusion machine for pelleting. Coarse blocks are then returned to the Chain Crusher for crushing. Because the product contains low moisture, it does not need to be dried. The granulation rate is usually about 85%.

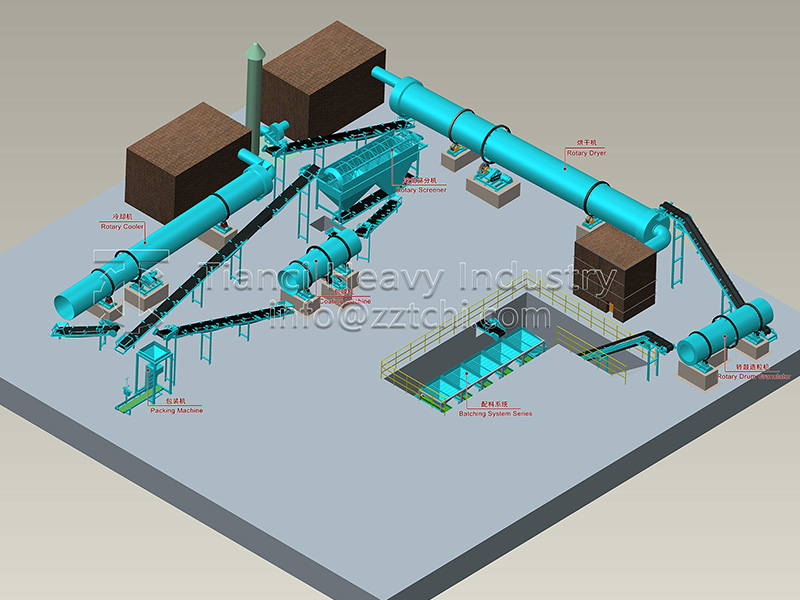

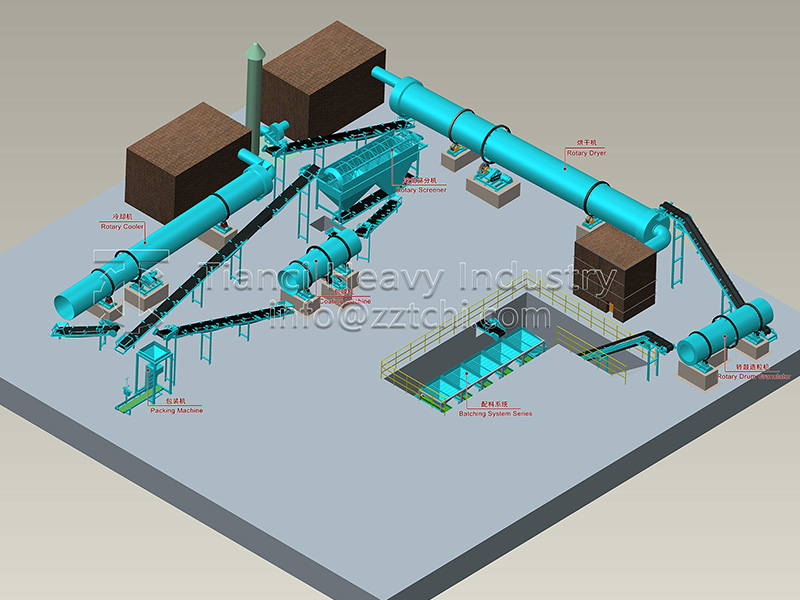

The extrusion granulation process of compound Fertilizer with an annual output of 10,000 to 20,000 tons is shown in the figure below (NPK Fertilizer Production Line) :

Due to the precipitation of water during the reaction process, the material becomes thin, wet and sticky. At the same time, the decomposition rate of urea increases, making granulation impossible. Therefore, in the formulation must be equipped with human calcium magnesium phosphate fertilizer or other fertilizers, such as potassium sulfate and potassium chloride.

In the extrusion granulation process, two basic fertilizers, calcium superphosphate and urea, cannot be used alone for production, because calcium superphosphate contains free acid, which chemically reacts with urea during extrusion as follows: H3PO4+CO (NH2) 2→CO (NH2) 2·H3PO4

Process analysis of Fertilizer Granules Compaction Machine production line

Selection of appropriate raw materials and preparation of mixtures are important factors in the production of qualified extruded fertilizers. Some raw materials can be mixed and extruded according to their respective characteristics. Such as potassium chloride, ammonium sulfate and urea are raw materials with good extrusion properties. Super phosphate, lime nitrogen [calcium cyanamide (CaCN2)], hard boron calcium stone and phosphate rock can be extruded, but they do not have as good extruding performance as the above raw materials. However, some fertilizers, such as super phosphate, can be pre-dried or extended its ripening period to improve its extruding performance. In terms of raw materials, other factors that affect the extrusion performance of products include: particle size distribution, moisture content, temperature, plasticity and hardness. Extrusion operation conditions include pressure, roller diameter and speed, roller surface and spacing between two rollers, etc. The PRACTICE SHOWS THAT USING ammonium sulfate, diam monium phosphate, super PHOSPHATE, potassium CHLORIDE and UREA (MOISTURE ≤1.5%) as raw materials, THE PRODUCTION of 13-13-21 and 15-15-15 compound fertilizers has obtained satisfactory results.

The materials that have been used for extrusion granulation are as follows:

Ammonium chloride urea monoammonium phosphate ammonium sulfate + dicyandiamide (cyanoguanidine)

Ammonium sulfate urinary aldehyde diammonium sulfate lime nitrogen [cyanamide calcium (CaCN2)]

Calcium sulfate phosphate ore vanadium sulfate gypsum (CaSO4·2H2O) peat mixture

Limestone heavy ore potassium chloride potassium chloride + trace element fertilizer

Organic fertilizer potassium sulfate NPK magnesium mixed fertilizer

Slow-acting fertilizer Port Gate phosphate fertilizer (acid slag)

Fertilizer Granules Compaction Machine has a wide range of applications and can graninate a variety of raw materials. So it is also known as ammonium sulfate compound fertilizer dry extrusion granulator, Fertilizer Granules Compaction Machine, potassium magnesium fertilizer Fertilizer Granules Compaction Machine, calcium chloride Fertilizer Granules Compaction Machine, dry ammonium sulfate roller granulator, compound fertilizer roller granulator, ammonium sulfate granulator, compound fertilizer extrusion granulator.

Fertilizer Granules Compaction Machine is the use of pressure to directly squeeze the material into the finished product granulation process, especially suitable for the granulation of thermal sensitive materials. There are usually two types of extrusion machinery: one is the push type granulator; The other is Fertilizer Granules Compaction Machine. The two types have various forms due to their different structures. The water content of the feed of the push and press type extrusion granulator is usually 5% ~ 8%, and the cylindrical product is obtained after extrusion, and the compound fertilizer product with water content less than 5% is obtained by cooling. The water content of the feed of the pelleting Fertilizer Granules Compaction Machine can be lower, foreign reports can be between 0.5% and 1.5%, the belt material obtained by extrusion is broken by the Chain Crusher, and the double screen is screened to get the bulk or compound fertilizer products with edges and angles. The fine powder after crushing is returned to the extrusion machine for pelleting. Coarse blocks are then returned to the Chain Crusher for crushing. Because the product contains low moisture, it does not need to be dried. The granulation rate is usually about 85%.

The extrusion granulation process of compound Fertilizer with an annual output of 10,000 to 20,000 tons is shown in the figure below (NPK Fertilizer Production Line) :

Due to the precipitation of water during the reaction process, the material becomes thin, wet and sticky. At the same time, the decomposition rate of urea increases, making granulation impossible. Therefore, in the formulation must be equipped with human calcium magnesium phosphate fertilizer or other fertilizers, such as potassium sulfate and potassium chloride.

In the extrusion granulation process, two basic fertilizers, calcium superphosphate and urea, cannot be used alone for production, because calcium superphosphate contains free acid, which chemically reacts with urea during extrusion as follows: H3PO4+CO (NH2) 2→CO (NH2) 2·H3PO4

Process analysis of Fertilizer Granules Compaction Machine production line

Selection of appropriate raw materials and preparation of mixtures are important factors in the production of qualified extruded fertilizers. Some raw materials can be mixed and extruded according to their respective characteristics. Such as potassium chloride, ammonium sulfate and urea are raw materials with good extrusion properties. Super phosphate, lime nitrogen [calcium cyanamide (CaCN2)], hard boron calcium stone and phosphate rock can be extruded, but they do not have as good extruding performance as the above raw materials. However, some fertilizers, such as super phosphate, can be pre-dried or extended its ripening period to improve its extruding performance. In terms of raw materials, other factors that affect the extrusion performance of products include: particle size distribution, moisture content, temperature, plasticity and hardness. Extrusion operation conditions include pressure, roller diameter and speed, roller surface and spacing between two rollers, etc. The PRACTICE SHOWS THAT USING ammonium sulfate, diam monium phosphate, super PHOSPHATE, potassium CHLORIDE and UREA (MOISTURE ≤1.5%) as raw materials, THE PRODUCTION of 13-13-21 and 15-15-15 compound fertilizers has obtained satisfactory results.

The materials that have been used for extrusion granulation are as follows:

Ammonium chloride urea monoammonium phosphate ammonium sulfate + dicyandiamide (cyanoguanidine)

Ammonium sulfate urinary aldehyde diammonium sulfate lime nitrogen [cyanamide calcium (CaCN2)]

Calcium sulfate phosphate ore vanadium sulfate gypsum (CaSO4·2H2O) peat mixture

Limestone heavy ore potassium chloride potassium chloride + trace element fertilizer

Organic fertilizer potassium sulfate NPK magnesium mixed fertilizer

Slow-acting fertilizer Port Gate phosphate fertilizer (acid slag)

Fertilizer Granules Compaction Machine has a wide range of applications and can graninate a variety of raw materials. So it is also known as ammonium sulfate compound fertilizer dry extrusion granulator, Fertilizer Granules Compaction Machine, potassium magnesium fertilizer Fertilizer Granules Compaction Machine, calcium chloride Fertilizer Granules Compaction Machine, dry ammonium sulfate roller granulator, compound fertilizer roller granulator, ammonium sulfate granulator, compound fertilizer extrusion granulator.