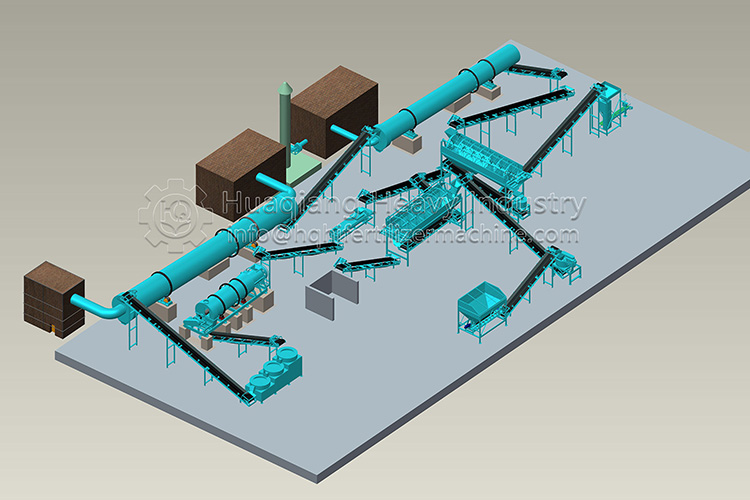

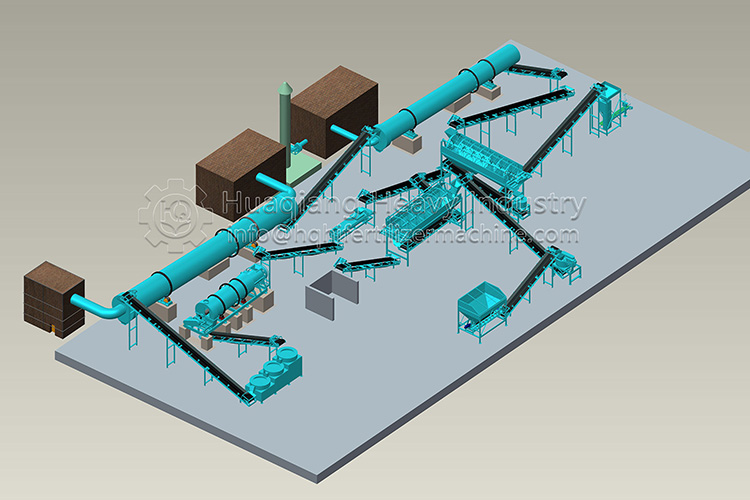

What equipment does it take to build an Organic Fertilizer Production Line?

Date:2024/08/20

The equipment required by the organic fertilizer production line is fermentation and throwing machine, organic fertilizer pulverizer, mixer, Rotary Drum Granulator, Rotary Drum Dryer, cooling machine, Rotary screening machine, automatic packaging machine, belt conveyor, coating machine, etc.

The production equipment using these organic fertilizers can process the raw materials rich in organic matter into ideal organic fertilizers for sale, thus making a profit.

The raw materials for the production of organic fertilizer are very wide, such as various livestock and poultry manure, urban sludge, animal and plant residues, etc. These raw materials are rich in organic matter, nitrogen, phosphorus, potassium and other nutrients for crop production, and the purchase price is low.

Working principle of Organic Fertilizer Production Line:

The processing of organic fertilizer is mainly the collection of raw materials, and then the ratio of raw materials according to the required formula, the adjustment of raw material moisture, carbon and nitrogen ratio, and the start of fermentation.

Windrow Compost Turning Machine : In the process of auxiliary fermentation, the raw material is turned and thrown, providing sufficient oxygen for the raw material, controlling the temperature, and making the raw material fermentation more uniform and sufficient.

Pulverizer: The size of the fermented material is not uniform, and the semi-wet material pulverizer can be used to finely crush it.

Disc Granulator: The crushed material is made into organic fertilizer particles with uniform size through the organic fertilizer granulator.

Drying and cooling machine: the organic fertilizer made into particles still contains about 30% moisture, in order to increase its strength, it is necessary to dry and cool the particles. It is also more conducive to later preservation and transportation.

Roller screen machine: after granulation, there will be a small number of unqualified particles, some are too large, some are too small, the use of screening machine will be screened out, too large return to the crusher, too small return to the granulator to re-granulation, qualified particles will flow into the automatic packaging machine.

Packaging machine: The use of automatic packaging machine will be finished organic fertilizer particles packaging, complete the whole processing process.

It should be noted that the above configuration is a conventional configuration of Organic Fertilizer Production Line, which will be slightly adjusted in the actual production process due to different formulas and production processes.

The production equipment using these organic fertilizers can process the raw materials rich in organic matter into ideal organic fertilizers for sale, thus making a profit.

The raw materials for the production of organic fertilizer are very wide, such as various livestock and poultry manure, urban sludge, animal and plant residues, etc. These raw materials are rich in organic matter, nitrogen, phosphorus, potassium and other nutrients for crop production, and the purchase price is low.

Working principle of Organic Fertilizer Production Line:

The processing of organic fertilizer is mainly the collection of raw materials, and then the ratio of raw materials according to the required formula, the adjustment of raw material moisture, carbon and nitrogen ratio, and the start of fermentation.

Windrow Compost Turning Machine : In the process of auxiliary fermentation, the raw material is turned and thrown, providing sufficient oxygen for the raw material, controlling the temperature, and making the raw material fermentation more uniform and sufficient.

Pulverizer: The size of the fermented material is not uniform, and the semi-wet material pulverizer can be used to finely crush it.

Disc Granulator: The crushed material is made into organic fertilizer particles with uniform size through the organic fertilizer granulator.

Drying and cooling machine: the organic fertilizer made into particles still contains about 30% moisture, in order to increase its strength, it is necessary to dry and cool the particles. It is also more conducive to later preservation and transportation.

Roller screen machine: after granulation, there will be a small number of unqualified particles, some are too large, some are too small, the use of screening machine will be screened out, too large return to the crusher, too small return to the granulator to re-granulation, qualified particles will flow into the automatic packaging machine.

Packaging machine: The use of automatic packaging machine will be finished organic fertilizer particles packaging, complete the whole processing process.

It should be noted that the above configuration is a conventional configuration of Organic Fertilizer Production Line, which will be slightly adjusted in the actual production process due to different formulas and production processes.