What raw materials are needed to mass manufacture organic fertilizers?

Date:2024/08/22

Organic fertilizer, as an indispensable part of agricultural production, is valued for its multiple effects of enhancing soil fertility, improving soil structure and promoting crop growth. Large-scale production of organic fertilizer requires not only high-quality raw materials, but also advanced production equipment. This paper will discuss the raw materials required for the production of organic fertilizer and the related equipment of fertilizer granulator.

The production raw materials of organic fertilizer mainly include agricultural waste, livestock and poultry manure, organic components in urban household garbage, industrial organic waste residue and so on. These raw materials can be converted into nutrient-rich organic fertilizers after fermentation, putrefication and other processes.

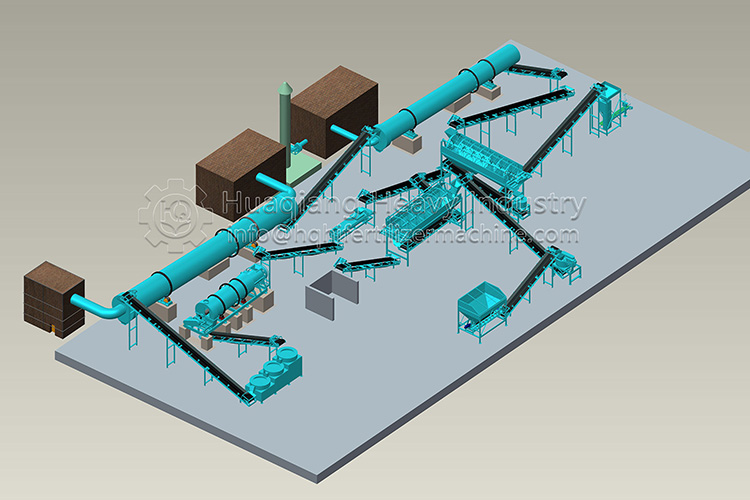

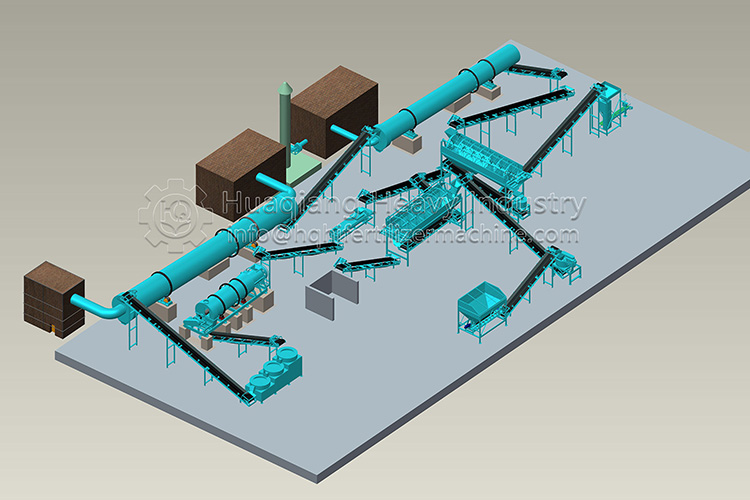

In the process of Organic Fertilizer Production Line, "fertilizer granulator series" equipment plays a vital role. Rotary Drum Granulator through the rotation of the drum, the raw material in the drum tumbling, friction, the formation of particles. This equipment is suitable for mass production and can guarantee the quality and consistency of fertilizer particles.

Disc Granulator Through the rotation of the disc, the raw material on the disc tumbling, agglomeration, the formation of uniform particles. This equipment is easy to operate, low maintenance cost, suitable for small and medium-sized organic fertilizer production enterprises.

In addition to the raw materials and equipment mentioned above, large-scale production of organic fertilizer also needs to consider factors such as production efficiency, environmental protection requirements and cost control. Through the reasonable selection of raw materials and granulator equipment, the quality and production efficiency of organic fertilizers can be ensured to meet the needs of modern agricultural production.

The production raw materials of organic fertilizer mainly include agricultural waste, livestock and poultry manure, organic components in urban household garbage, industrial organic waste residue and so on. These raw materials can be converted into nutrient-rich organic fertilizers after fermentation, putrefication and other processes.

In the process of Organic Fertilizer Production Line, "fertilizer granulator series" equipment plays a vital role. Rotary Drum Granulator through the rotation of the drum, the raw material in the drum tumbling, friction, the formation of particles. This equipment is suitable for mass production and can guarantee the quality and consistency of fertilizer particles.

Disc Granulator Through the rotation of the disc, the raw material on the disc tumbling, agglomeration, the formation of uniform particles. This equipment is easy to operate, low maintenance cost, suitable for small and medium-sized organic fertilizer production enterprises.

In addition to the raw materials and equipment mentioned above, large-scale production of organic fertilizer also needs to consider factors such as production efficiency, environmental protection requirements and cost control. Through the reasonable selection of raw materials and granulator equipment, the quality and production efficiency of organic fertilizers can be ensured to meet the needs of modern agricultural production.