Screening technology empowerment: Application and optimization strategy of screening equipment in organic fertilizer production lines

Date:2024/07/16

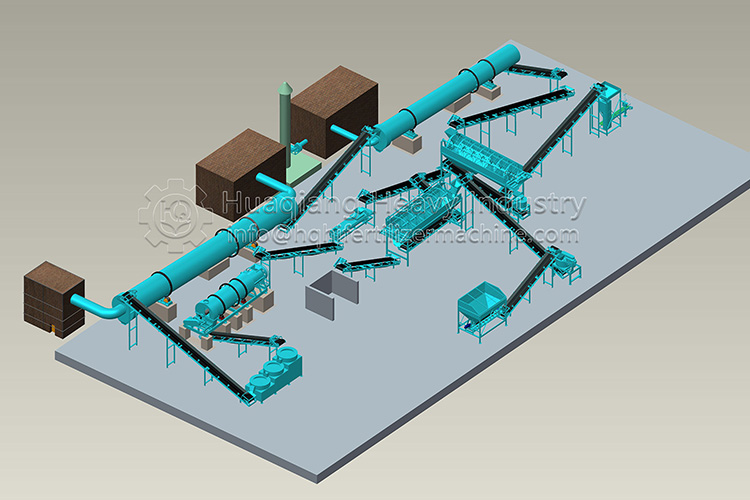

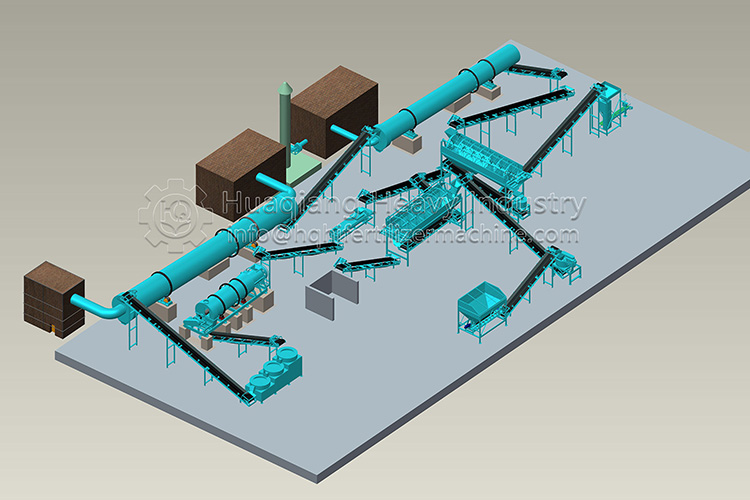

In the modern organic fertilizer production line, screening equipment as a key link, its importance is self-evident. From Rotary Screener Machine to Vibration Screener Machine, these efficient and accurate screening devices not only improve production efficiency, but also ensure the quality and consistency of organic fertilizer products.

Rotary Screener Machine: solid backing for raw material pretreatment

With its unique rolling screening mechanism, the Rotary Screener Machine has become the first checkpoint on the organic fertilizer production line. It can effectively remove large particles, impurities and components that do not meet the particle size requirements in raw materials, and provide a clean and uniform raw material basis for subsequent processing. The continuous operation ability of the Rotary Screener Machine and the adjustable screen aperture make it able to adapt to different types and different states of organic fertilizer raw materials, and provide a strong guarantee for the smooth operation of the production line.

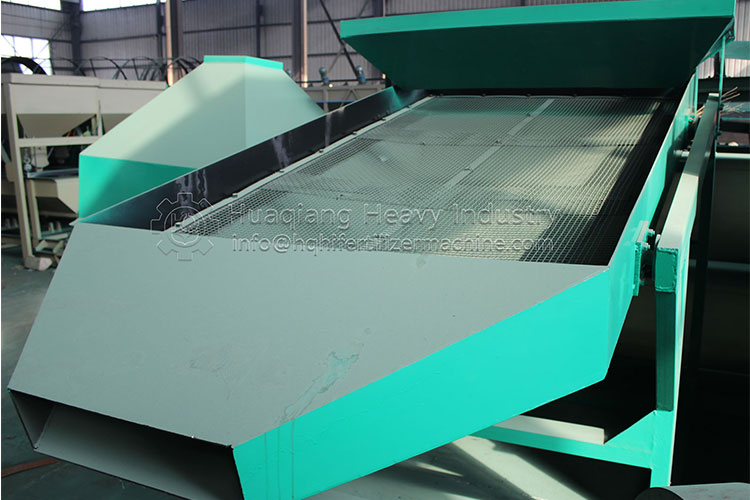

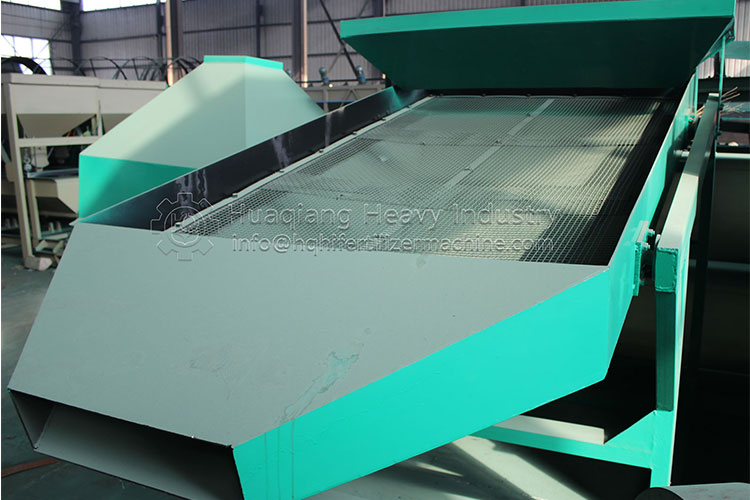

Vibrating screen: the wise choice of fine grading

Entering the fine processing stage, the Vibration Screener Machine shows outstanding performance with its high frequency vibration and multi-layer screen design. It can subdivide raw materials into multiple particle size segments according to production needs to meet the fertilizer needs of different application scenarios. The high screening efficiency and automatic adjustment function of the Vibration Screener Machine not only improve the uniformity and quality of the product, but also significantly reduce energy consumption and labor costs.

Optimization strategy: Intelligence leads the future

In the face of increasingly fierce market competition and environmental protection requirements, the screening equipment of organic fertilizer production line is also constantly optimized and upgraded. The application of intelligent technology makes the screening equipment can monitor the production status in real time and automatically adjust the parameters to achieve the optimal screening effect. At the same time, through data analysis and predictive maintenance, potential problems can be identified and resolved in advance, ensuring the continuity and stability of the production line.

The application and optimization of screening equipment in organic fertilizer production lines is an important force to promote the development of the industry in the direction of high efficiency, environmental protection and intelligence. In the future, with the continuous progress and innovation of technology, screening equipment will play a more important role in the production of organic fertilizer and contribute more to the sustainable development of agriculture.

Rotary Screener Machine: solid backing for raw material pretreatment

With its unique rolling screening mechanism, the Rotary Screener Machine has become the first checkpoint on the organic fertilizer production line. It can effectively remove large particles, impurities and components that do not meet the particle size requirements in raw materials, and provide a clean and uniform raw material basis for subsequent processing. The continuous operation ability of the Rotary Screener Machine and the adjustable screen aperture make it able to adapt to different types and different states of organic fertilizer raw materials, and provide a strong guarantee for the smooth operation of the production line.

Vibrating screen: the wise choice of fine grading

Entering the fine processing stage, the Vibration Screener Machine shows outstanding performance with its high frequency vibration and multi-layer screen design. It can subdivide raw materials into multiple particle size segments according to production needs to meet the fertilizer needs of different application scenarios. The high screening efficiency and automatic adjustment function of the Vibration Screener Machine not only improve the uniformity and quality of the product, but also significantly reduce energy consumption and labor costs.

Optimization strategy: Intelligence leads the future

In the face of increasingly fierce market competition and environmental protection requirements, the screening equipment of organic fertilizer production line is also constantly optimized and upgraded. The application of intelligent technology makes the screening equipment can monitor the production status in real time and automatically adjust the parameters to achieve the optimal screening effect. At the same time, through data analysis and predictive maintenance, potential problems can be identified and resolved in advance, ensuring the continuity and stability of the production line.

The application and optimization of screening equipment in organic fertilizer production lines is an important force to promote the development of the industry in the direction of high efficiency, environmental protection and intelligence. In the future, with the continuous progress and innovation of technology, screening equipment will play a more important role in the production of organic fertilizer and contribute more to the sustainable development of agriculture.