Precise mixing, the source of quality: Analysis of the key role of mixing equipment on the quality of organic fertilizer

Date:2024/07/17

In the refined era of organic fertilizer production, mixing equipment as a key link, its choice is directly related to the final quality of organic fertilizer. Today, we focus on the "Horizontal Mixer", "Double Axis Mixer" and "Vertical Disc Mixer", and explore in depth how they affect the uniformity, nutrient distribution and overall performance of organic fertilizers.

Horizontal Mixer: efficient and uniform, laying the foundation of quality

Horizontal Mixer with its unique structural design, to ensure that the material in the mixing process of full flow and uniform mixing. Its cylindrical design not only increases the contact area between the materials, but also makes the nutrients in the raw materials more evenly dispersed among the particles through the shearing and kneading action of the rotating mixing arm. This efficient and uniform mixing effect lays a good quality foundation for organic fertilizer, ensuring the balanced release of nutrients and effective absorption of crops.

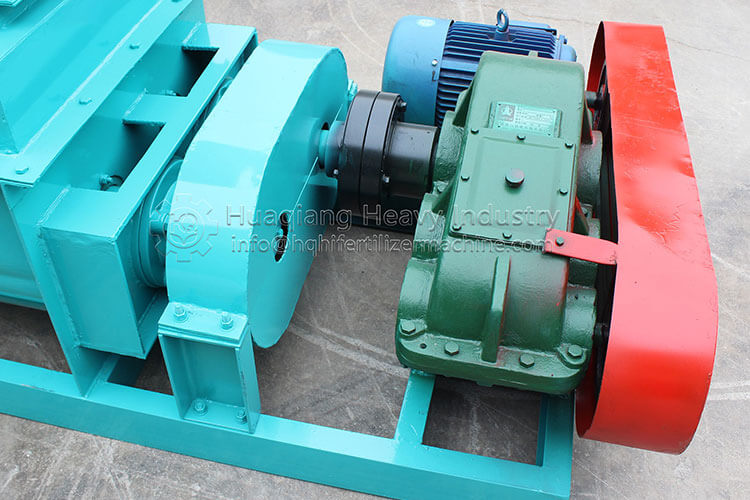

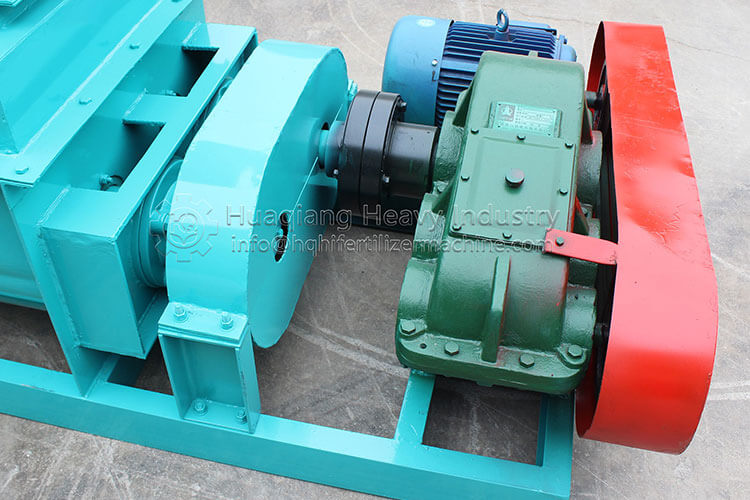

Double Axis Mixer: strong mixing, improve quality stability

The Double Axis Mixer, with its unique advantage of dual-axis synchronous reverse rotation, produces strong shear and extrusion force in the mixing process. This strong mixing effect can not only completely break the caking phenomenon between the particles of the material, but also make the raw materials of different components more closely combined to form a stable mixture. This is essential to improve the quality stability of organic fertilizers, ensuring that each batch of products can meet a consistent high standard.

Vertical Disc Mixer: flexible and versatile to meet individual needs

And the Vertical Disc Mixer with its flexible characteristics, to meet the individual needs of organic fertilizer production. The disc design enables the material to form multi-layer flow during the mixing process, and the precise control of different mixing effects can be achieved by adjusting the rotation speed and Angle of the disc. This flexibility not only improves production efficiency, but also enables the production of organic fertilizers to be customized according to different raw material characteristics and market demand, further enhancing the market competitiveness of products.

Horizontal Mixer: efficient and uniform, laying the foundation of quality

Horizontal Mixer with its unique structural design, to ensure that the material in the mixing process of full flow and uniform mixing. Its cylindrical design not only increases the contact area between the materials, but also makes the nutrients in the raw materials more evenly dispersed among the particles through the shearing and kneading action of the rotating mixing arm. This efficient and uniform mixing effect lays a good quality foundation for organic fertilizer, ensuring the balanced release of nutrients and effective absorption of crops.

Double Axis Mixer: strong mixing, improve quality stability

The Double Axis Mixer, with its unique advantage of dual-axis synchronous reverse rotation, produces strong shear and extrusion force in the mixing process. This strong mixing effect can not only completely break the caking phenomenon between the particles of the material, but also make the raw materials of different components more closely combined to form a stable mixture. This is essential to improve the quality stability of organic fertilizers, ensuring that each batch of products can meet a consistent high standard.

Vertical Disc Mixer: flexible and versatile to meet individual needs

And the Vertical Disc Mixer with its flexible characteristics, to meet the individual needs of organic fertilizer production. The disc design enables the material to form multi-layer flow during the mixing process, and the precise control of different mixing effects can be achieved by adjusting the rotation speed and Angle of the disc. This flexibility not only improves production efficiency, but also enables the production of organic fertilizers to be customized according to different raw material characteristics and market demand, further enhancing the market competitiveness of products.