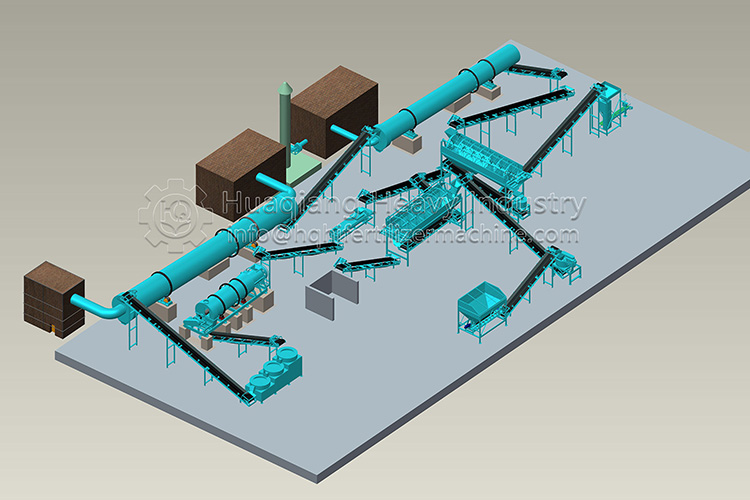

Design and optimization of organic fertilizer granulation production line

Date:2024/07/13

In the wave of sustainable development of modern agriculture, the design and optimization of organic fertilizer granulation production line has become a key link to improve agricultural production efficiency and promote resource recycling. The design and optimization of Organic Fertilizer Granulator Production Line is a systematic project, which needs to consider raw material characteristics, production requirements, equipment performance and the application of intelligent and automated technology. Through scientific and reasonable planning and layout, an efficient, intelligent and environmentally friendly organic fertilizer production system can be created to contribute to the sustainable development of agriculture.

One, raw material pretreatment: fine grinding, laying a good foundation for granulation

The primary link of organic fertilizer production is raw material pretreatment, which is directly related to the success or failure of subsequent granulation. The use of Chain Crusher, Half-Wet Material Crusher, Straw Crusher and other efficient crushing equipment can ensure that the raw materials are finely crushed to the appropriate particle size, improve the mixing uniformity, and create good conditions for the subsequent granulation process. Especially for raw materials containing large particles or long fibers, such as crop straw, the application of straw shredder is particularly important.

Two, granulation link: diversified selection to meet different needs

In the pelletizing process, the production line can flexibly choose a variety of equipment such as Disc Granulaor (Pan Granulator), Rotary Drum Granulator, New Type Organic Fertilizer Granulator and even Hydraulic Roller Granulator、Double Roller Press Granulator according to the characteristics of raw materials and production needs. For example, for high humidity, high viscosity materials, drum granulator with its strong mixing and molding capabilities become the first choice; In the pursuit of high efficiency and uniform particles, the disc granulator stands out with its stable performance. The emergence of the New Type Two-In-One Organic Fertilizer Granulator is to combine the two steps of mixing and granulation into one, further simplifying the production process and improving production efficiency.

Three, drying and cooling: to ensure product quality, improve storage stability

The organic fertilizer particles that have been granulated need to be dried by a Drum Fertilizer Dryer to remove excess water and prevent mildew and deterioration. Subsequently, the Drum Fertilizer Cooler quickly reduces the material temperature to prevent high temperature damage to the particles, while improving the storage stability of the product. The intelligent control of this link can precisely adjust the temperature and humidity to ensure the consistency and stability of product quality.

Four, screening and packaging: fine processing, enhance market competitiveness

Screening is an important step to ensure product quality. Through screening equipment such as Drum Screener Machine or Vibration Screener Machine, unqualified particles and impurities can be removed to improve the purity and appearance quality of the product. Finally, through automated packaging equipment, qualified organic fertilizer particles are packaged for easy transportation and sales. The intelligent packaging system can flexibly adjust the packaging specifications and styles according to the market demand, and enhance the market competitiveness of products.

Five, intelligent, automation: improve production efficiency, reduce operating costs

In the overall design and optimization of organic fertilizer pelletizing production line, the application of intelligent and automated technology is an indispensable part. From the automatic loading of raw materials to the automatic packaging of products, the entire production process can be monitored and adjusted in real time through advanced control systems. This not only greatly improves production efficiency, but also reduces labor costs and the occurrence of human errors. At the same time, the intelligent data analysis function can provide enterprises with accurate production data and market feedback, and help enterprises timely adjust production strategies and optimize resource allocation.

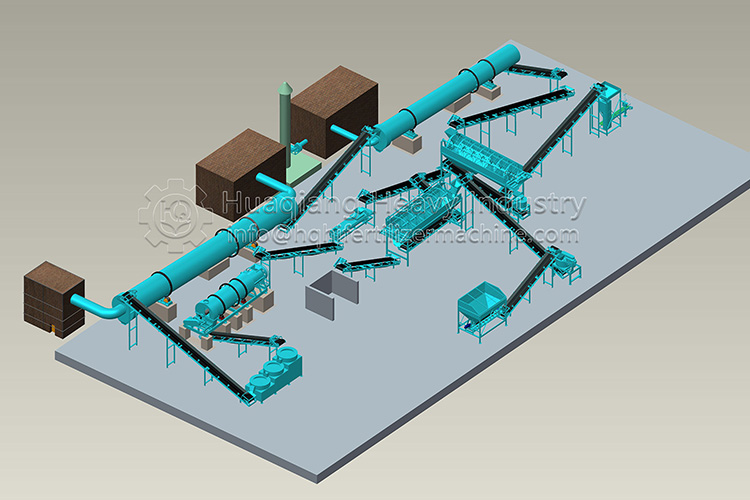

One, raw material pretreatment: fine grinding, laying a good foundation for granulation

The primary link of organic fertilizer production is raw material pretreatment, which is directly related to the success or failure of subsequent granulation. The use of Chain Crusher, Half-Wet Material Crusher, Straw Crusher and other efficient crushing equipment can ensure that the raw materials are finely crushed to the appropriate particle size, improve the mixing uniformity, and create good conditions for the subsequent granulation process. Especially for raw materials containing large particles or long fibers, such as crop straw, the application of straw shredder is particularly important.

Two, granulation link: diversified selection to meet different needs

In the pelletizing process, the production line can flexibly choose a variety of equipment such as Disc Granulaor (Pan Granulator), Rotary Drum Granulator, New Type Organic Fertilizer Granulator and even Hydraulic Roller Granulator、Double Roller Press Granulator according to the characteristics of raw materials and production needs. For example, for high humidity, high viscosity materials, drum granulator with its strong mixing and molding capabilities become the first choice; In the pursuit of high efficiency and uniform particles, the disc granulator stands out with its stable performance. The emergence of the New Type Two-In-One Organic Fertilizer Granulator is to combine the two steps of mixing and granulation into one, further simplifying the production process and improving production efficiency.

Three, drying and cooling: to ensure product quality, improve storage stability

The organic fertilizer particles that have been granulated need to be dried by a Drum Fertilizer Dryer to remove excess water and prevent mildew and deterioration. Subsequently, the Drum Fertilizer Cooler quickly reduces the material temperature to prevent high temperature damage to the particles, while improving the storage stability of the product. The intelligent control of this link can precisely adjust the temperature and humidity to ensure the consistency and stability of product quality.

Four, screening and packaging: fine processing, enhance market competitiveness

Screening is an important step to ensure product quality. Through screening equipment such as Drum Screener Machine or Vibration Screener Machine, unqualified particles and impurities can be removed to improve the purity and appearance quality of the product. Finally, through automated packaging equipment, qualified organic fertilizer particles are packaged for easy transportation and sales. The intelligent packaging system can flexibly adjust the packaging specifications and styles according to the market demand, and enhance the market competitiveness of products.

Five, intelligent, automation: improve production efficiency, reduce operating costs

In the overall design and optimization of organic fertilizer pelletizing production line, the application of intelligent and automated technology is an indispensable part. From the automatic loading of raw materials to the automatic packaging of products, the entire production process can be monitored and adjusted in real time through advanced control systems. This not only greatly improves production efficiency, but also reduces labor costs and the occurrence of human errors. At the same time, the intelligent data analysis function can provide enterprises with accurate production data and market feedback, and help enterprises timely adjust production strategies and optimize resource allocation.