Technology of converting empty fruit bunches of oil palm into fertilizer

Date:2024/07/31

On the road of sustainable agricultural development, the application of organic fertilizer is increasingly extensive, and the process of transforming the waste of oil palm empty fruit string into efficient fertilizer through modern science and technology is a vivid practice of green circular economy.

Windrow Compost Turning Machine: the "turning master" of compost fermentation

Compost fermentation is a crucial step in the process of converting oil palm bunches into organic fertilizer. As the "soil turning master" of this link, the Windrow Compost Turning Machine ensures that the compost material can be evenly heated and fully ventilated, promote the activity of microorganisms, and accelerate the decomposition of organic matter through its powerful tilting ability. Especially during the critical stage of fermentation, the machine is able to regularly turn the pile, adjust the water content of the material, avoid local overheating or anaerobic environment, thus ensuring the smooth fermentation process and the final production of high-quality organic fertilizer.

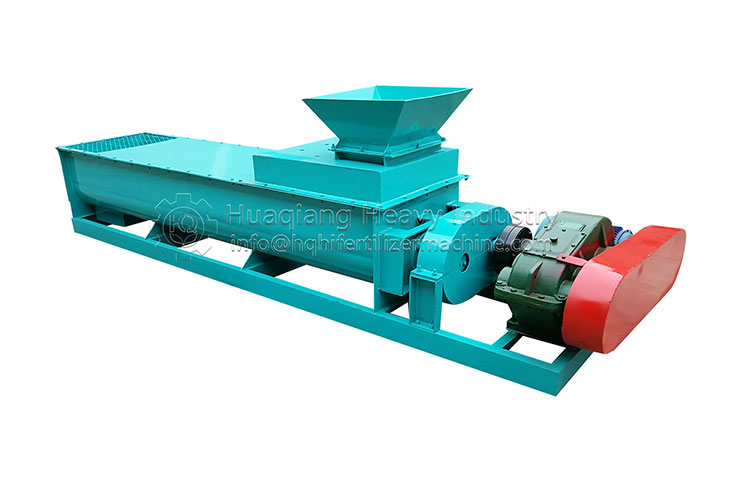

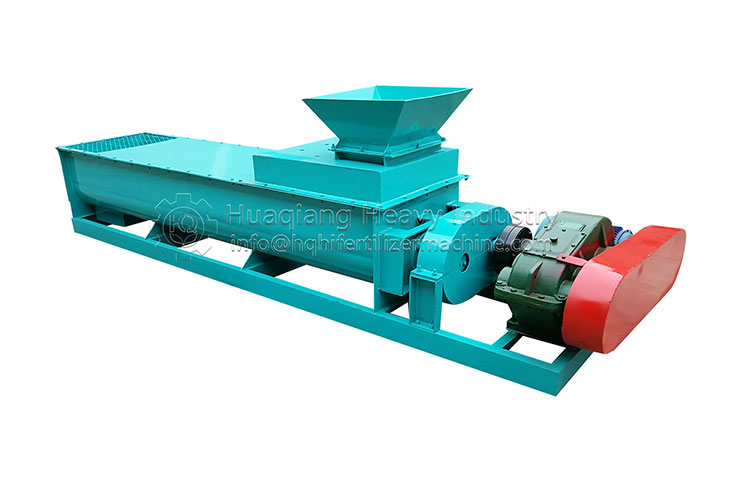

Double Shafts Paddles Mixer: "Master Blender" for even mixing

In the process of adding auxiliary materials and spraying water, the Double Shafts Paddles Mixer plays an irreplaceable role. With its unique Double Shafts design, the equipment is able to efficiently mix the auxiliary materials such as sludge, turf soil, fiber fermentation bacteria, urea and oil palm fruit silk, ensuring that each part of the material can evenly absorb water and nutrients. By precisely controlling the mixing ratio and water content of the material, a solid foundation is laid for the subsequent fermentation process, and the initial transformation from waste to valuable fertilizer is achieved.

Flat-Die Pellet Machine: The "molding master" of particle molding

After a series of complex fermentation processes, the empty fruit bunches of oil palm are finally transformed into organic materials rich in nutrients. However, in order to make these materials more convenient for application in agricultural production, Flat-die pellet machine came into being. This equipment uses advanced extrusion granulation technology to process fully fermented materials into cylindrical particles, the diameter of which can be adjusted between 0.8-10cm according to demand. Through the processing of the Flat-die pelleting machine, the organic fertilizer not only looks neat, is easy to store and transport, but also can release nutrients more evenly during use and improve the fertilizer utilization rate.

Windrow Compost Turning Machine: the "turning master" of compost fermentation

Compost fermentation is a crucial step in the process of converting oil palm bunches into organic fertilizer. As the "soil turning master" of this link, the Windrow Compost Turning Machine ensures that the compost material can be evenly heated and fully ventilated, promote the activity of microorganisms, and accelerate the decomposition of organic matter through its powerful tilting ability. Especially during the critical stage of fermentation, the machine is able to regularly turn the pile, adjust the water content of the material, avoid local overheating or anaerobic environment, thus ensuring the smooth fermentation process and the final production of high-quality organic fertilizer.

Double Shafts Paddles Mixer: "Master Blender" for even mixing

In the process of adding auxiliary materials and spraying water, the Double Shafts Paddles Mixer plays an irreplaceable role. With its unique Double Shafts design, the equipment is able to efficiently mix the auxiliary materials such as sludge, turf soil, fiber fermentation bacteria, urea and oil palm fruit silk, ensuring that each part of the material can evenly absorb water and nutrients. By precisely controlling the mixing ratio and water content of the material, a solid foundation is laid for the subsequent fermentation process, and the initial transformation from waste to valuable fertilizer is achieved.

Flat-Die Pellet Machine: The "molding master" of particle molding

After a series of complex fermentation processes, the empty fruit bunches of oil palm are finally transformed into organic materials rich in nutrients. However, in order to make these materials more convenient for application in agricultural production, Flat-die pellet machine came into being. This equipment uses advanced extrusion granulation technology to process fully fermented materials into cylindrical particles, the diameter of which can be adjusted between 0.8-10cm according to demand. Through the processing of the Flat-die pelleting machine, the organic fertilizer not only looks neat, is easy to store and transport, but also can release nutrients more evenly during use and improve the fertilizer utilization rate.