Organic fertilizer protection measures

Date:2024/07/26

Protection measures for organic fertilizers during storage and transportation

In the storage and transportation of organic fertilizer, it is very important to take effective measures to ensure its stable quality and no loss of nutrients. Today, we will discuss how to use advanced organic fertilizer equipment, such as fertilizer granulator series, fertilizer crusher series, fertilizer mixer series, fertilizer screening machine series, fertilizer drying, cooling machine series and fertilizer coating machine series, to strengthen the protection measures of organic fertilizer.

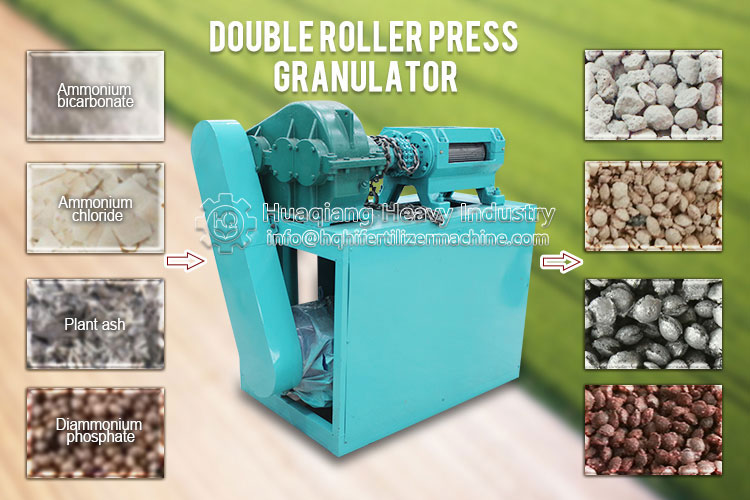

First of all, the raw materials are processed into pellets through the New Type Organic Fertilizer Granulator or the Double Roller Press Granulator, which can not only improve the compressive strength of the organic fertilizer, reduce the crushing during the storage process, but also facilitate the uniform distribution of transportation and fertilization. Granulated organic fertilizer is easier to maintain its internal water balance and prevent mildew.

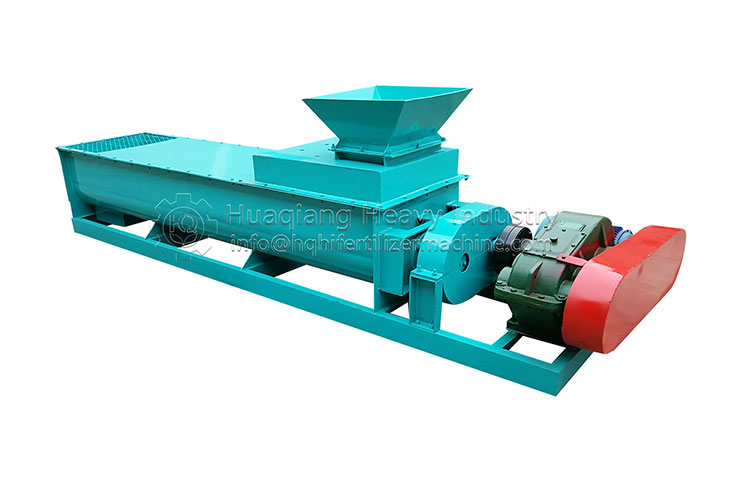

Next, before storage, the raw materials are refined using the Chain Crusher or Half-Wet Material Crusher to ensure uniform particle size, which helps to improve the storage effect. At the same time, the application of Drum Screener Machine and Vibration Screener Machine can fine screen organic fertilizer before storage, remove impurities and ensure product quality.

During storage, regular inspection and use of Horizontal Mixer or Double Axis Mixer to turn, can effectively prevent organic fertilizer caking, maintain its loose state, promote air circulation, reduce humidity accumulation, prevent mold deterioration. In addition, the combination of Drum Fertilizer Dryer and Drum Fertilizer Cooler can adjust the humidity of organic fertilizer when necessary to further improve its storage stability.

Before transportation, consider using the Coating Machine to wrap organic fertilizer particles. This protective film can isolate external water and oxygen, slow down the release rate of nutrients, and protect the quality of organic fertilizer in long-distance transportation.

From granulation, grinding, mixing, screening, drying and cooling to the coating, every link is inseparable from the support of professional organic fertilizer equipment. Reasonable selection and correct use of these devices can significantly improve the protection effect of organic fertilizers in the storage and transportation process, and provide high-quality and efficient organic fertilizers for agricultural production.